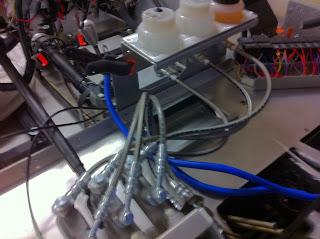

A very productive day has been spent connecting up all of the cooling system hoses. I am using the stock water manifold on the back of the Duratec block as I am running out of budget and could not afford a custom water rail. The photo to the right shows the heater outlet sealed off (yes I will be cold in winter!) and the bleed line is plumbed back to the left side of the car where the expansion tank will be installed on the scuttle. I have since changed the screw clamp for a stock Ford spring clamp.

Next I needed to route the water outlet from the manifold back to the right side of the block and down the front to the radiator. A good look through the CBS Online catalogue in the UK solved this problem both quickly and elegantly. I can't recommend these guys enough. Not only do they have everything you could ever conceivably need to build a kit car, they are not expensive, and this order shipped from the UK on Tuesday and arrived on Friday the same week! The solution was a 180 degree radiator hose bend attached to the manifold.

I then connected this to a 150mm beaded aluminum tube that has a 42mm radiator cap mount welded into it. The design of this system is important as this is to be the highest point in the system meaning all air bubbles should rise to this point. The 150mm aluminum tube is then connected to a modified 90 degree hose that routes the water line down the side of the block. I just now need to add a 580mm beaded aluminum pipe from here down to the radiator top hose. I will mount the water temp sender here as well.

The missing aluminum pipe will be connected to the block with rubber lined P-clips which will stabilise the entire hose system. I may also add an additional brace to the radiator cap tube. I am very impressed with how this has turned our given that it was designed on a web site and ordered without being able to test it first. From here it was down to the front to finish off the radiator outlet to thermostat line. I used a flexible 280mm hose from the radiator outlet, which threads through the steering rack.

This connects to the thermostat inlet hose via a 150mm aluminum beaded connector and three hose clamps. The hose here is 1mm bigger than the connector, so I am expecting leaks under pressure. As the hose just touches the down tube on the space frame, I have added a sacrificial liner to the space frame to protect the hose. Directly above the thermostat inlet is the 18mm inlet that normally connects to the return from the heater. I have been able to salvage the original hose and connectors for this, and after a few modifications been able to connect this hose back to the EGR valve and then on to where the expansion tank will sit. All in all today's work has been very fiddly, but very satisfying as I have been able to design and build something beautiful from new parts, and also salvage and recreate something I need from old parts.

Here on the left you can see where I have clamped off one of the T piece connectors and the main hose runs back under the inlet manifold to the EGR valve. I still need to fit the alternator in under all this, and the cable tie of the rest of the hoses and wiring looms. Next job is to start adding the front fuel and return lines for the fuel rail and the evaporative purge valve. As it was very cold day in Sydney, today was not with out many painful skinned knuckles and cuts on the hands and arms from reaching into tight engine spaces to mount hoses and clamps. I am ordering the fuel filters and regulators this week and hope to get those on next week. I will publish a To Do list soon of what needs to be done pre the first start.

To finish the back of the fuel system off I need a few parts. Because I didn't use the Focus in tank pump, I have to add an external fuel pressure regulator, and obviously I also need a high pressure filter. The filter is an OEM part from Nissan used in the Sylvia and Pathfinder, and purchased more so because it fit inside this cool-> alloy bracket. It is mounted on the bulkhead behind the passengers seat. I have also purchased a SARD fuel pressure regulator. Because the Duratec uses a returnless fuel rail, I need to regulate pressure after the pump, then return excess fuel directly to the tank. This means the SARD regulator needs three barbed connectors (pump, rail, return). I have grabbed some Permatex thread sealant to ensure I have no leakages as well. The first two connectors went in easily and are now sealed.

To finish the back of the fuel system off I need a few parts. Because I didn't use the Focus in tank pump, I have to add an external fuel pressure regulator, and obviously I also need a high pressure filter. The filter is an OEM part from Nissan used in the Sylvia and Pathfinder, and purchased more so because it fit inside this cool-> alloy bracket. It is mounted on the bulkhead behind the passengers seat. I have also purchased a SARD fuel pressure regulator. Because the Duratec uses a returnless fuel rail, I need to regulate pressure after the pump, then return excess fuel directly to the tank. This means the SARD regulator needs three barbed connectors (pump, rail, return). I have grabbed some Permatex thread sealant to ensure I have no leakages as well. The first two connectors went in easily and are now sealed.